Step inside Gotopower’s Shenzhen manufacturing facility. See our latest December 2025 production scene featuring automated laser welding, strict BMS testing, and LiFePO4 quality control. Your trusted BESS partner.

Excellence in Motion: An Exclusive Look Inside the Gotopower Factory

At Gotopower (gotopess.com), we believe that the quality of an Energy Storage System (BESS) isn’t just about the spec sheet—it’s about the precision of the manufacturing process.

As we wrap up a busy year, our production lines in Shenzhen are running at full capacity to meet the growing demand from our partners in the United States, Mexico, Peru, and across the globe. Today, we are sharing exclusive, behind-the-scenes photos taken on December, 2025, to show you exactly how your batteries are made.

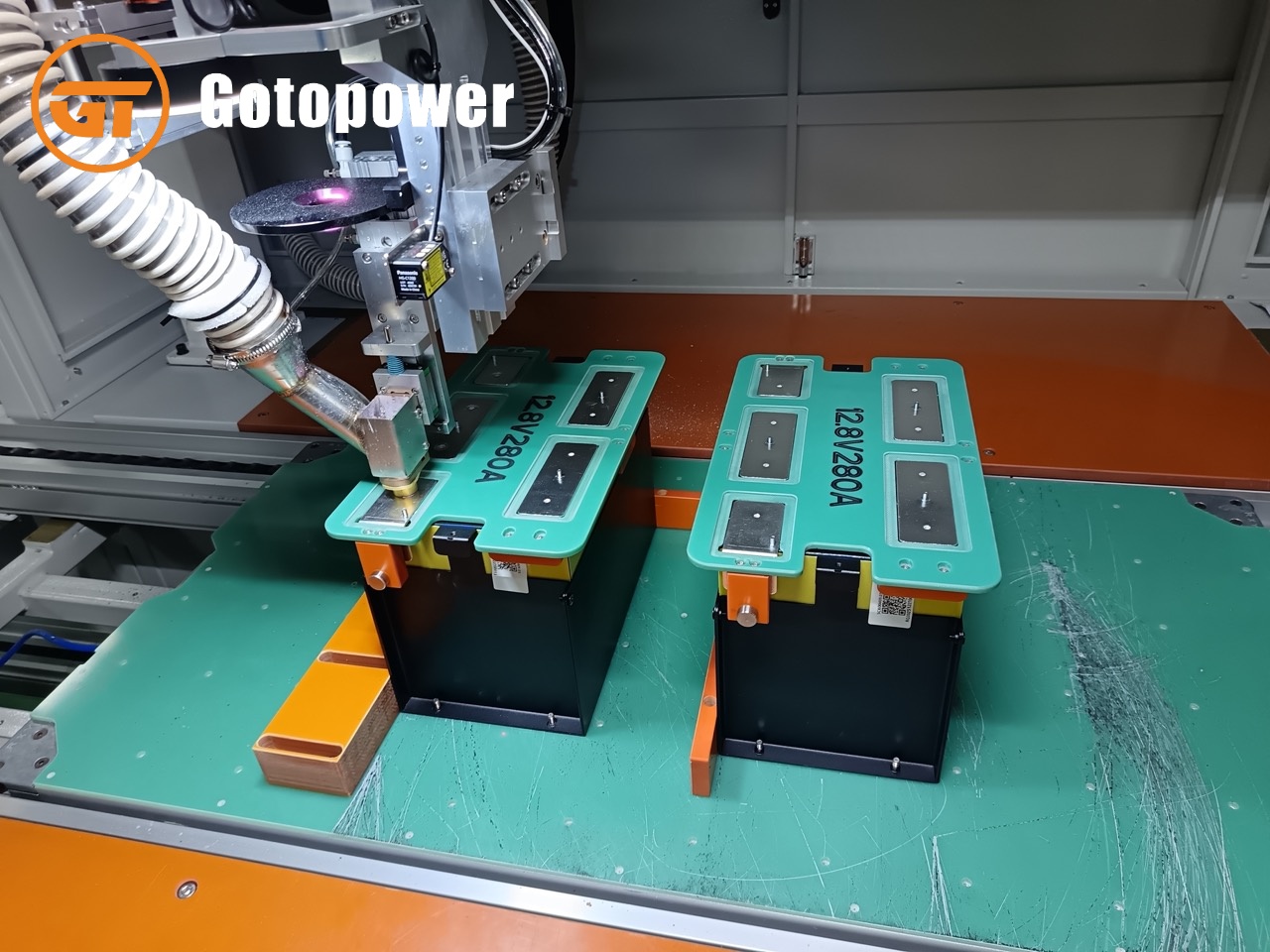

Precision Engineering: The Art of Laser Welding

One of the most critical steps in manufacturing high-performance LiFePO4 batteries is the connection between cells.

Automated laser welding machine bonding busbars to LiFePO4 battery terminals at Gotopower factory.

As seen in our production line, we utilize advanced automated laser welding technology. Unlike traditional manual screwing or soldering, laser welding ensures:

-

Lower Internal Resistance: Improving the overall efficiency of the battery pack.

-

Higher Structural Strength: Withstanding vibration during transportation and installation.

-

Consistency: Every weld is identical, reducing the risk of human error.

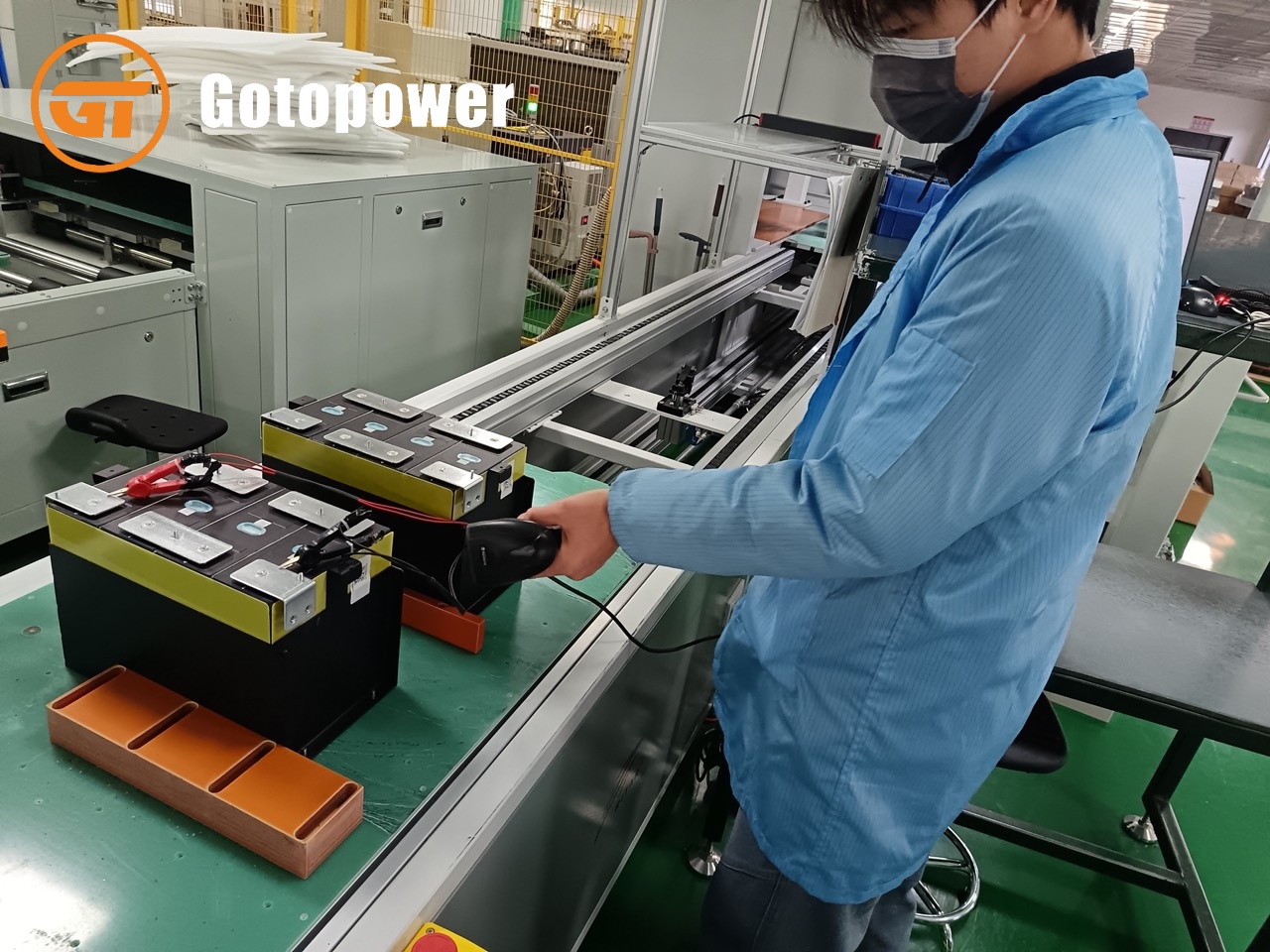

The Brain of the Battery: BMS Integration

A battery without a smart brain is just a container of energy. Our Battery Management System (BMS) is the guardian of safety and longevity.

High-quality BMS circuit boards ready for assembly into Gotopower energy storage batteries.

Our technicians meticulously prepare and test every BMS board before integration. Whether for a 5kWh residential unit or a commercial energy storage cabinet, our BMS ensures protection against overcharging, over-discharging, and short circuits, guaranteeing the 6000+ cycle life we promise to our customers.

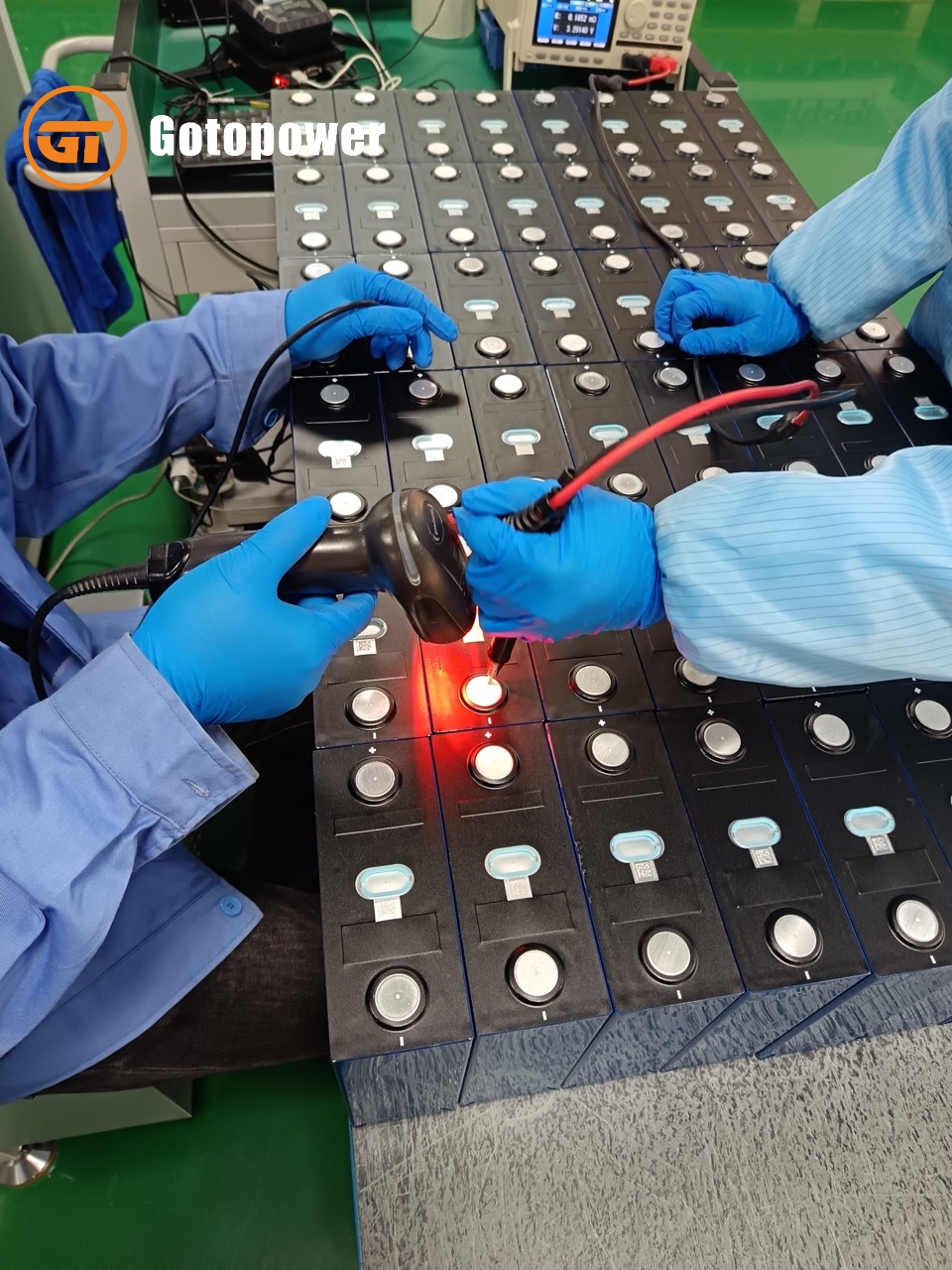

Zero Defects: Traceability and Quality Control

How do we ensure that every battery leaving our Shenzhen factory meets international standards (UL/CE)? The answer is traceability.

Quality control technicians scanning QR codes on prismatic LiFePO4 cells for digital traceability.

In the photo above, you can see our QA team using digital scanners to record the data of every single prismatic cell. This process creates a “digital passport” for each battery pack.

-

Voltage Matching: Ensuring all cells in a pack have identical voltage.

-

Capacity Grading: Preventing the “barrel effect” where one weak cell limits the whole pack.

-

Full Accountability: If any issue arises, we can trace it back to the specific production batch and raw material source.

Ready for the Global Market

From the meticulous manual assembly of casings to the final voltage testing of the finished modules, our Shenzhen team combines craftsmanship with automation.

We are not just a supplier; we are your manufacturing partner. Whether you are a solar distributor in the United States, Mexico, Peru, or another country looking for OEM services or an EPC contractor needing reliable off-grid solutions, Gotopower’s factory is ready to deliver.

Interested in visiting our production line or requesting a sample? Contact us today at sales@gotopess.com or explore our full product catalog at gotopess.com.